Industrial Chillers

Air Cooled Chillers

HC Series

Our air-cooled industrial chillers are widely used in the plastic industry, where precision temperature control is required when cooling molds to achieve higher quality of the product surface finish and lower cycle time.

THE AIR COOLED CHILLER HC SERIES IS A POWERFUL AND EFFICIENT WATER COOLING SYSTEM

Air cooled chillers are also intended for numerical-controlled (NC) lathes, die-casting machines, lasers, foodstuff and medical apparatus, and plating process machines. The compact and portable characteristics are best for machine side cooling.

Our portable air-cooled chillers contain all of the necessary components: a refrigeration circuit, a water reservoir, and a water pump. The controls of our air-cooled chiller units are integrated to include all contactor starters and require a simple electrical connection.

Our air-cooled chillers are designed for heavy-duty service, equipped with a Copeland Scroll Compressor, Siemens electrical components, and Plate Type Evaporator heat exchanger to maximize efficiency and reliability. Our industrial chillers are designed for indoor use only.

Air cooled industrial chillers are intended for the plastics industry, where precision temperature control is required when cooling mold temperatures to achieve higher quality of the product surface finish and lower cycle time. Industrial chillers are intended for numerical-controlled lathes, die-casting machines, lasers, foodstuff and medical apparatus, and plating process.

The compact and portable characteristics are best for machine side cooling.

IMPORTANCE OF AIR COOLED CHILLER HC SERIES

The Air Cooled Chiller HC Series is a powerful and efficient water-cooling system that is perfect for industrial and commercial applications. The unit features a Copeland compressor that is capable of providing cool water at temperatures as low as 5 degrees Celsius.

The Air Cooled Chiller HC Series also features a highly efficient evaporator that helps to reduce energy costs. The Air Cooled Chiller HC Series is an ideal choice to lower the temperature of machinery and process fluids by removing heat from the system and transferring it somewhere else.

POWER SUPPLY:

- 3 Phase 208V/220V/240V 60Hz

- 3 Phase 460V/480V 60Hz

Browsing the web for the best air-cooled industrial chillers on sale? Buy Small Chillers Online at W and Z Machinery Systems. Reach us today!

Check out our other products: Standard hopper dryers supplier

FEATURES INCLUDE:

- Has accurate temperature controller. Water temperature may range from 4.4C to 25C ( 39.9F to 77F)

- LCD Display. Digital controller with self-diagnostic features

- Advanced technology Copeland scroll compressor

- High and low refrigeration liquid-filled pressure gauges,high and low pressure switches, phase monitor

- Maximum heat exchange

- Open-type stainless steel water tank and piping

- Unique design for durability and easy maintenance

- Sensitive alarm and control system

- Portable

- Temperature Controller

- Evaporator

- Water Tank

- Drying Filter

- Air Cooling Condenser

- Height Pressure Switch

- Compressor

- Low Pressure Switch

- Water Pump

- Expansion Valve

- Temperature Controller

- Evaporator

- Water Tank

- Drying Filter

- Air Cooling Condenser

- Height Pressure Switch

- Compressor

- Low Pressure Switch

- Water Pump

- Expansion Valve

| Model: Air-Cooled | WZHC-3ACI | WZHC-5ACI | WZHC-8ACI | WZHC-10ACI | WZHC-15ACI | WZHC-20ACI | WZHC-25ACI | ||

| Cooling Capacity | Tons | 3 | 5 | 8 | 10 | 15 | 20 | 25 | |

| BTU | 30,047 | 50,192 | 90,140 | 112,676 | 180,000 | 240,000 | 300,000 | ||

| Compressor | All-Close Scroll | ||||||||

| Compressor Power | Hp | 4.6 | 7.4 | 10 | 13.4 | 2 x 9.4 | 2 x 12 | 2 x 14 | |

| Kw | 3.4 | 5.5 | 7.5 | 10 | 2 x 7 | 2 x 9 | 2 x 10.5 | ||

| Refrigerant | R-407C Freon | ||||||||

| Full Load Amps | |||||||||

| 220/3/60 | Amps | 12 | 25 | 33 | 45 | 72 | 90 | 101 | |

| 460/3/60 | Amps | 7 | 12 | 18 | 24 | 35 | 44 | 50 | |

| Water Pump | |||||||||

Power | Hp | 1 | 1 | 2 | 2 | 4 | 5.4 | 5.4 | |

| Kw | 0.75 | 0.75 | 1.5 | 1.5 | 3 | 4 | 4 | ||

| Flow Rate | GPM | 19 | 19 | 30 | 30 | 36 | 48 | 60 | |

| L/min | 70 | 70 | 113 | 113 | 136 | 182 | 227 | ||

| Pressure | Psi | 38 | 38 | 28 | 28 | 45 | 45 | 45 | |

| Process Connections | Inch (npt) | 1″ | 1″ | 1.5″ | 1.5″ | 2″ | 2″ | 2″ | |

| Water Tank Capacity | Gal | 14 | 16 | 28 | 32 | 48 | 84 | 84 | |

| Lit | 52 | 60 | 108 | 122 | 183 | 320 | 320 | ||

| Condenser | |||||||||

| No. of Fans | 1 | 1 | 2 | 2 | 4 | 4 | 4 | ||

| Power | Hp | 0.33 | 0.8 | 0.67 | 1.12 | 1.60 | 2.25 | 2.25 | |

| Kw | 0.25 | 0.6 | 0.50 | 0.84 | 1.20 | 1.68 | 1.68 | ||

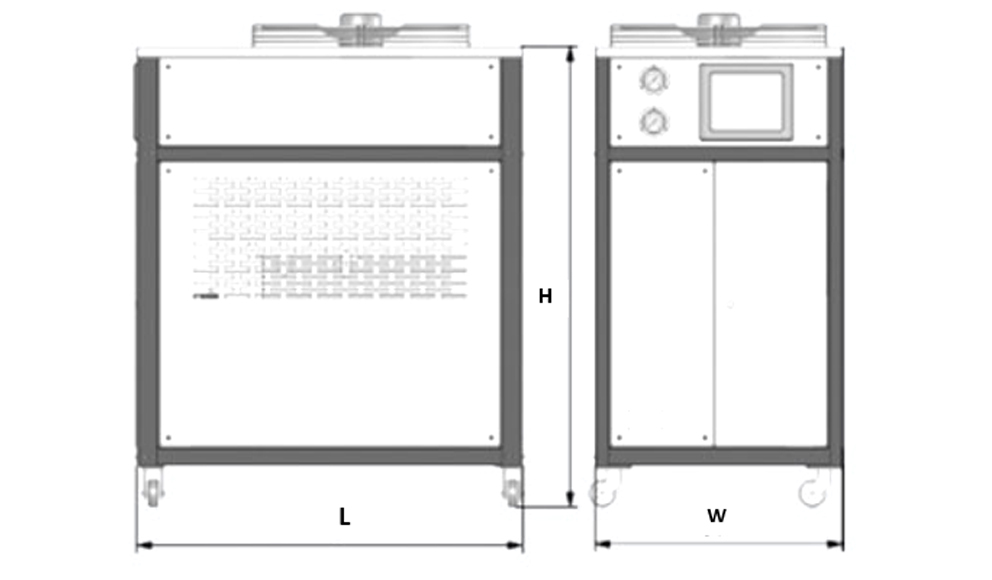

| Dimensions | |||||||||

| Length | mm | 1067 | 1067 | 1170 | 1170 | 1680 | 1860 | 1870 | |

| Inch | 42 | 42 | 46 | 46 | 66 | 73.25 | 73.50 | ||

| Width | mm | 673 | 673 | 770 | 870 | 1170 | 1450 | 1170 | |

| Inch | 26.50 | 26.50 | 30.50 | 34.25 | 46 | 57 | 46 | ||

| Height | mm | 1244 | 1244 | 1600 | 1700 | 1760 | 1880 | 1860 | |

| Inch | 49 | 49 | 63 | 67 | 69.25 | 74 | 73.25 | ||

| Weight | kg | 192 | 218 | 370 | 400 | 550 | 780 | 950 | |

| lb | 422 | 480 | 814 | 880 | 1210 | 1716 | 2090 | ||